- 5 min reading time

- PVC & Umwelt

PVC & Environment

What is PVC?

PVC (polyvinyl chloride) is a plastic (plastic). One of its most important features is that it can be deformed and kept permanently elastic with the addition of plasticizers (additives). How elastic depends on the proportion and type of plasticizers. This is referred to as soft PVC (flexible PVC).

Commonly used plastics:

Polyvinyl chloride (PVC)

Polypropylene (PP)

Polyethylene (PE)

Polystyrene (PS)

Polyethylenterephthalat (PET)

Polycarbonat (PC)

Polyurethane (PU)

Fields of application of PVC

In addition to soft PVC, there is also hard PVC. It contains no plasticizers and is hard in its material properties, but also brittle. It is virtually non-elastic and can break under high loads. Typical products made of hard PVC are window profiles and pipes. It is not suitable for use in floor coverings, for example.

Compared to other plastics, soft PVC has special material properties that predestine it for certain areas of application within the construction sector. These include all types of interiors: from factory floors to public buildings to private homes - with floor coverings, cables, wall foils, roofing membranes, etc. Soft PVC, depending on the type, is resilient, well insulating, low maintenance, weather resistant, flame retardant, acid, oil and water resistant.

For many years, soft PVC has been the subject of criticism, primarily because of the proven hazardous effects of the added plasticizers on health and the environment. Among the best-known and most frequently used representatives is the group of phthalates.

Commonly used plastics:

DIDP (diisodecyl phthalate)

DINP (Diisononyl phthalate)

DEHP (diethylhexyl phthalate)

DBP (dibutyl phthalate)

BBP (benzyl butyl phthalate)

PVC is not environmentally friendly

PVC is a substance in great conflict with the environment and thus with human health in all areas, from production to use, recycling and disposal - both directly and indirectly.

The direct health hazard refers mainly to soft PVC (soft PVC). This includes the risk of cancer and hormonal changes.

Problem: Production

PVC consists essentially of oil and rock salt. Drilling for and processing crude oil are fundamentally harmful to the environment, although of course other plastics such as PP (polypropylene) also require crude oil. Toxic chlorine is extracted from rock salt by electro-chemical means during the production of PVC. This chlorine is needed for the production of PVC.

A health hazard to humans is already present in the manufacturing process. Vinyl chloride alone (a starting material for PVC) can cause cancer and mutagenic effects in humans. In Germany, the maximum permissible workplace concentration for PVC in the air we breathe is 0.3 mg/m³.

Problem: Use and health risks

The focus here is on soft PVC. With the help of plasticizers, PVC can be kept elastic. This is a property that makes soft PVC so indispensable for cables or floor coverings, for example. Such products are exposed to constant stresses that would quickly cause them to break without plasticizers.

Phthalates in particular are carcinogenic and affect the endocrine system. Contact with them can hardly be avoided. When PVC is enriched with plasticizers, a new compound is formed, but it is not insoluble. Over time, depending on various factors such as UV radiation, temperature, contact with water, skin or saliva, these plasticizers escape again - in liquid or gaseous form. Rule of thumb: the softer the end product, the more plasticizers it contains.

Info!

Every now and then you can find references such as PVC is not toxic or as good as non-toxic. But be careful! Toxic says nothing about whether something is carcinogenic.

Problem: Disposal

Issues such as the disposal of PVC are always subject to the way in which they are formulated.

The added plasticizers of the phthalate group evaporate, are washed out or rub off and thus get into the soil and also into the groundwater. They are biodegradable, but this naturally takes time.

Hard PVC has no plasticizers. However, it is also not biodegradable. Nevertheless, hard PVC must be replaced regularly, for example in the construction sector, because it is not UV-resistant.

The duration of UV resistance depends on the location as well as the atmospheric conditions prevailing there, such as solar radiation, temperature, humidity, reflectivity of snow etc. In the case of outdoor pipes made of hard PVC, the Fachverband der Kunststoffrohr-Industrie (Professional Association of the Plastic Pipe Industry) states that, as a rule, the first physical impairments occur after one to two years.

So hard PVC crumbles, but it doesn't dissolve. It goes to landfills and stays there - unless someone gets the idea to burn it.

Burning PVC is not an adequate solution from the point of view of environmental impact. It is flame retardant and requires a lot of energy. In addition, there is a risk of releasing the chlorine used in its production, as well as other dioxins and aromatics (chemical group), which are carcinogenic.

Problem: Recycling

Recycling describes the recovery of raw materials from PVC products, for example, in order to produce new PVC products of equal value again, if possible.

Efficiency in the recovery of raw materials is almost always dependent on the degree of grade purity of the material. There are processes that can be used to convert mixed plastic waste into gases, waxes and oils that can be recycled as raw materials. One problem here so far is the question of what happens to the recovered plasticizers.

One answer to this, for example, could be the EU-funded project coordinated by the Fraunhofer Institute for Process Engineering and Packaging (IVW). »Circular Flooring« which will run until 2023. Several European countries are involved in this project. The aim is not only to recycle the PVC to a high standard. The plasticizers added will be completely separated and recycled using chemical processes so that they are a) non-critical and b) can be used again as plasticizers.

"Noncritical" means harmless in the sense of the REACH, the European Chemicals Regulation on the Registration, Evaluation, Authorization and Restriction of Chemicals.

In principle, however, the use of critical plasticizers and heavy metal-based stabilizers represents a hitherto unsolved challenge in the recycling of PVC waste up to the year 2015. The sometimes long product life of several decades, especially of PVC windows, pipes and flooring, means that contaminated material would continue to circulate in the recycling loop for a long time. Plastics such as polypropylene (PP) and PET do not require these additives and are therefore much easier to recycle.

Info!

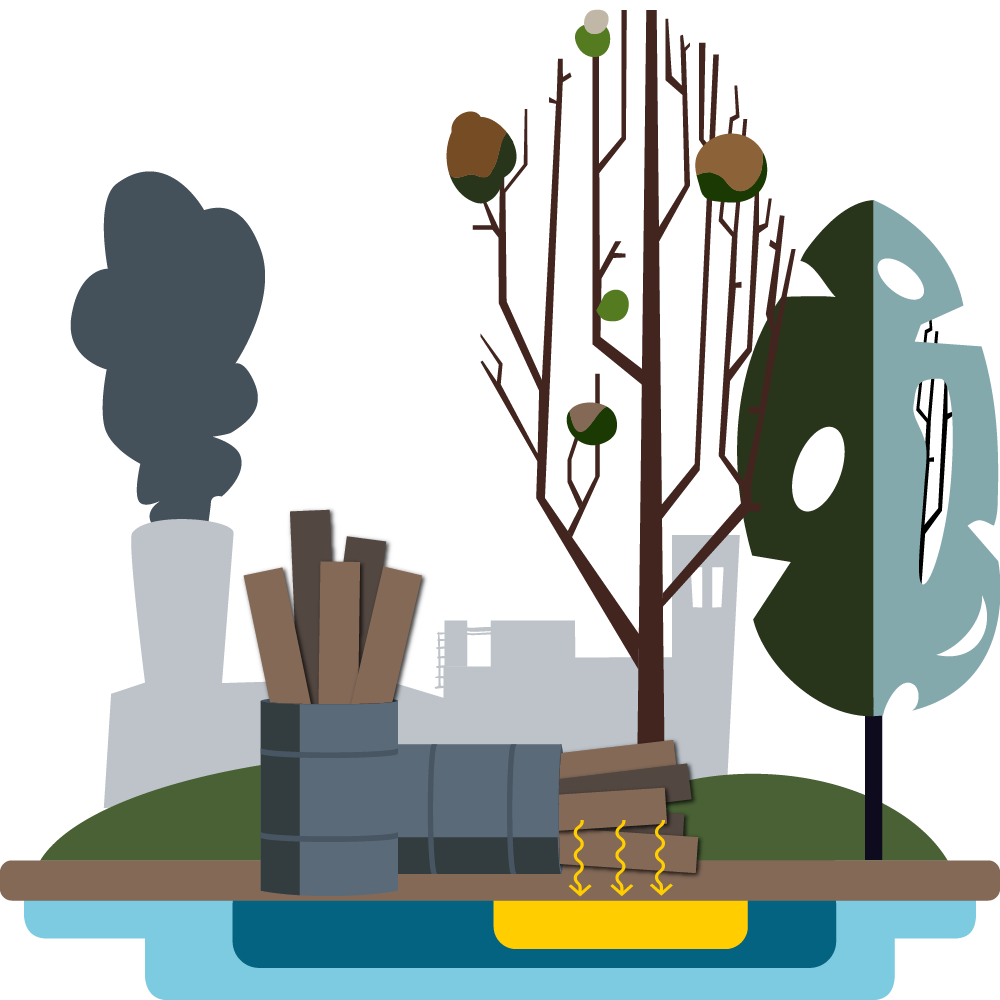

In principle, only small proportions of plastics are currently recycled. According to a study published in February 2022 by the OECD (Organization for Economic Cooperation and Development), global plastic production nearly doubled between 2000 and 2019.

• Of the waste from this period, 9 percent was recycled.

• 19 percent were burned.

• Fifty percent was dumped in landfills.

• 22 percent were disposed of illegally.

Recommendation

According to current knowledge, the use of PVC is subject to a trade-off between health hazards and environmental pollution on the one hand and economic reasons on the other. With up-to-date information and PVC-free products, we would like to help raise awareness of the importance and consequences of such a trade-off.

Important background and findings on this topic are provided by recognized scientific studies. In this case, for example: "The use of PVC (polyvinyl chloride) in the context of a non-toxic environment (EU Final Report, January 2022)."

We are happy to offer you further important information, including tips on PVC alternatives, differences between vinyl, PVC and linoleum, labels such as the Blue Angel and more, in other articles in the "PVC-free" section.